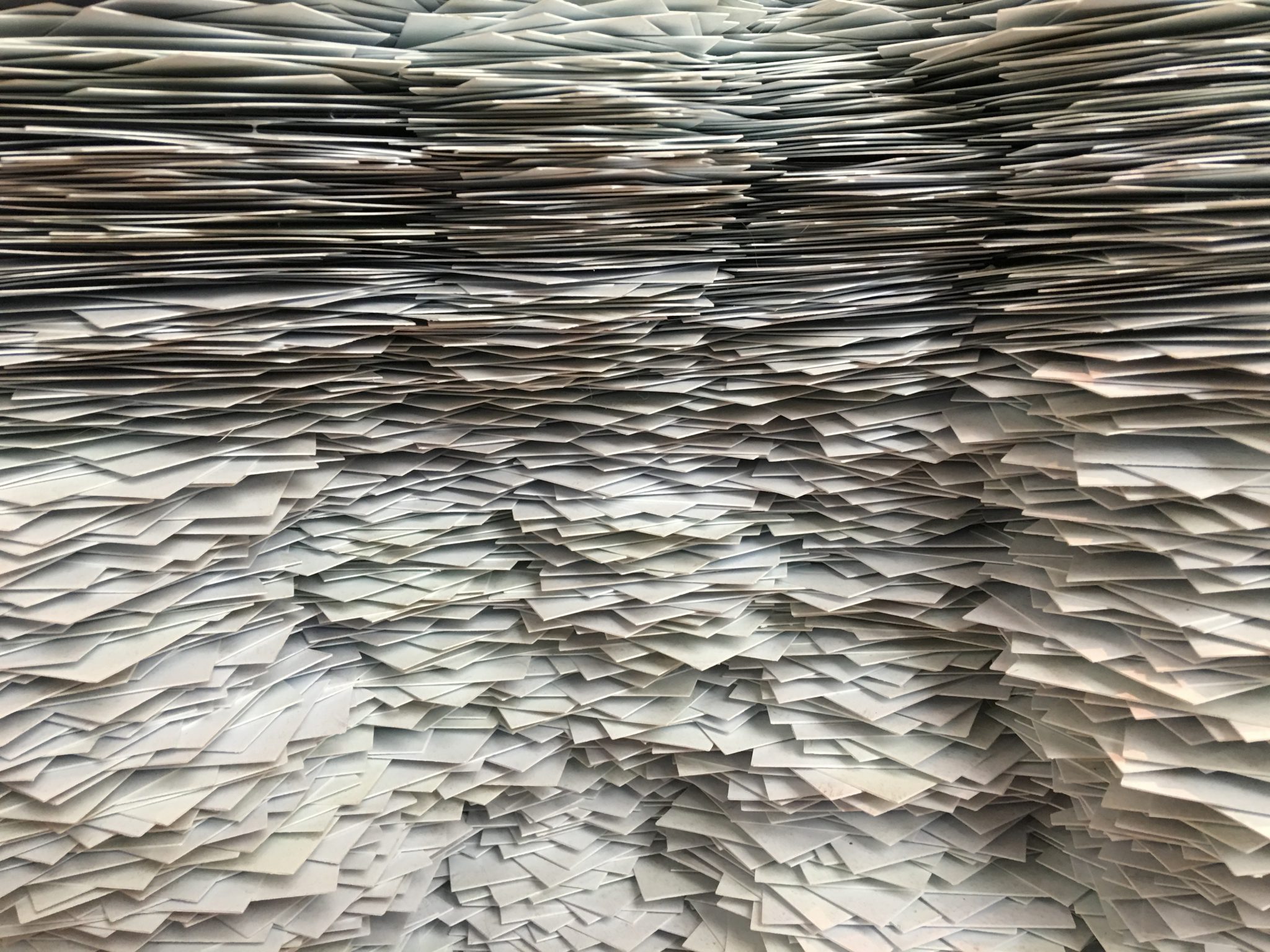

As part of it’s deregulation agenda, the Australian Government states it is “committed to improving the quality of its regulation, including minimising the burden of regulation on businesses, community organisations and individuals”. I’m not so sure this is true. Compliance reporting requirements are increasing and this in turn is raising costs of operating a small […]

Contact Form

Just fill in your details below.